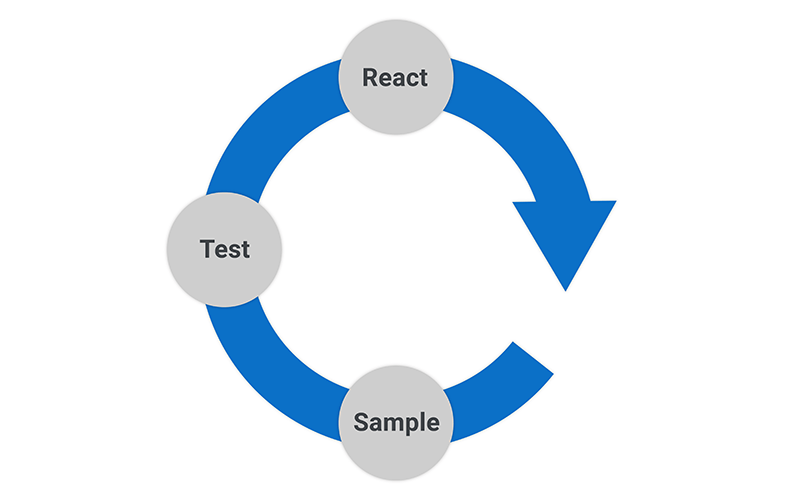

AXI’s fuel sampling and testing equipment enables equipment managers to gain a thorough understanding of their fuel quality. With our sampling equipment, users are able to pull fuel samples from problematic areas of the fuel tank where contaminants often reside. Once the fuel samples are collected, AXI offers a number of comprehensive options for fuel testing. AXI International recommends the following simple 4-step protocol when it comes to regular fuel testing to maintain fuel reliability.

1. Sample

Collect Fuel Samples

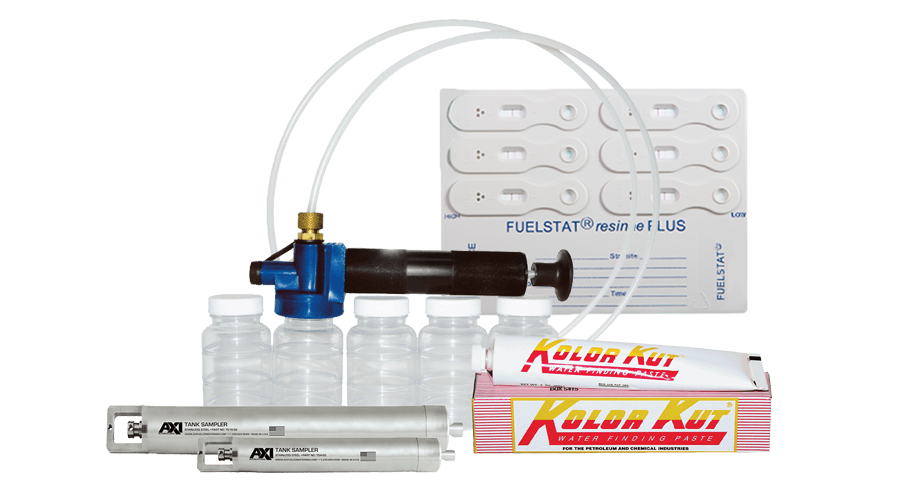

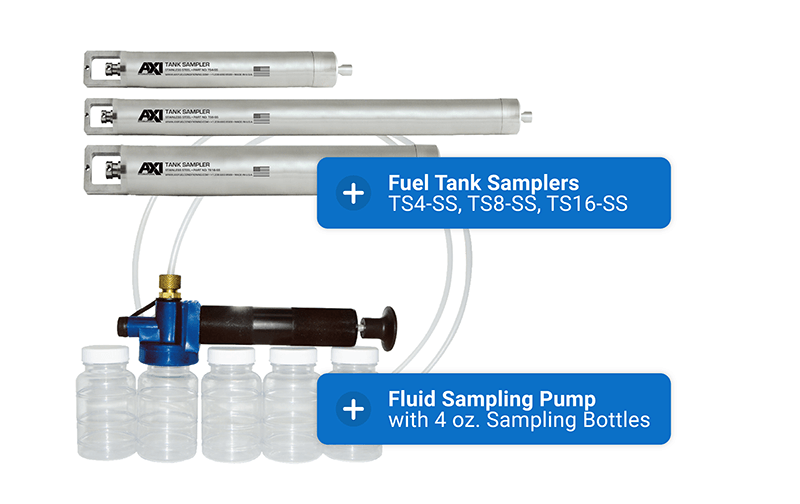

Pull fuel samples from hard to reach and problematic areas that typically harbor high levels of fuel contamination with a fluid sampling pump or fuel tank sampler (also known as "bacon bombs").

2. Test

Check For Contamination

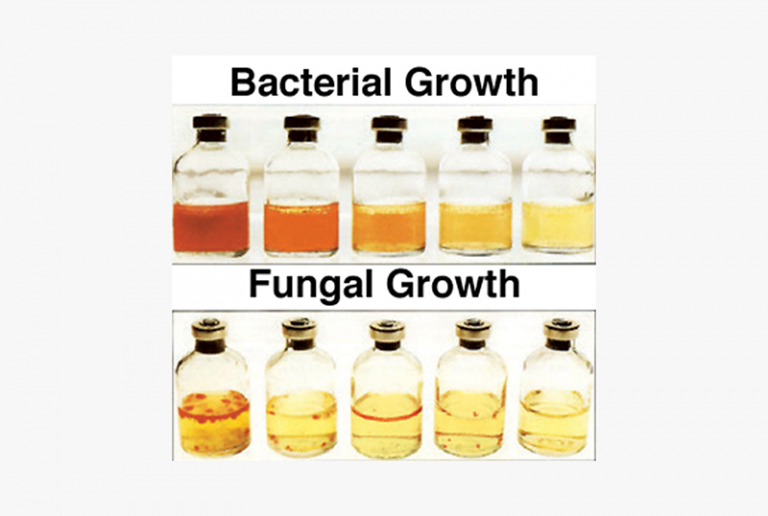

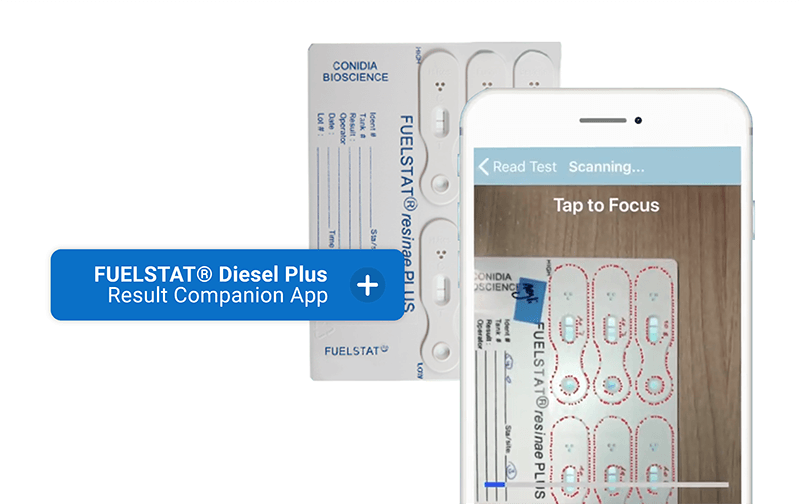

Test fuel samples on-site for microbial contamination with an ASTM D6469 compliant FUELSTAT® instant test kit. Send samples off for lab inspection with Liqui-Cult microbial test kits. Quickly determine if water is present in the tank with KolorKut® water finding paste.

3. React

Remediate & Maintain Fuel Quality

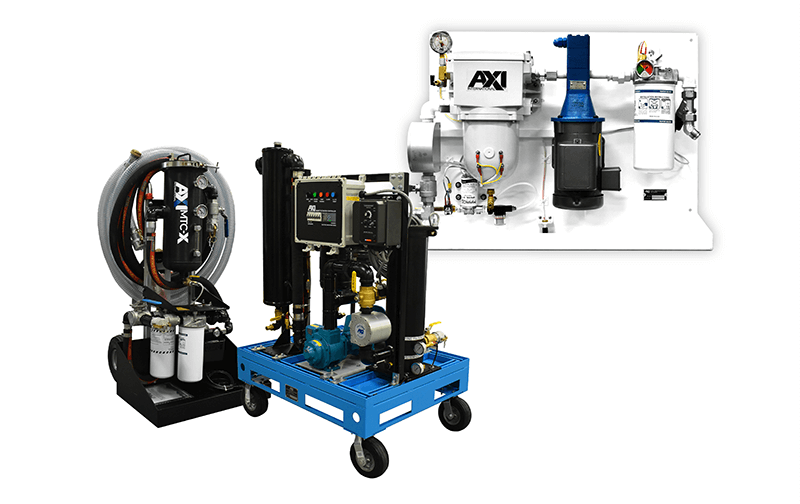

Remove and prevent future fuel contamination with one of AXI's many fuel filtration solutions. Remediate heavily contaminated fuel with a mobile fuel polishing system (MTC) or local service. Automatically filter fuel on a routine basis, maintaining fuel cleanliness, with a compact (FPS) or enclosed (STS) fuel maintenance system.

4. Repeat

Routinely Check Fuel Quality

It is extremely important to regularly test for fuel contamination, especially for mission critical facilities.

Bringing fuel back to ISO 4406 specification does not mean that it will remain that way long-term. Fuel often falls out of specification through natural degradation, microbial growth, and the introduction of new contaminants via fuel transferring and new fuel loads. Be proactive and unnecessary prevent downtime.

Bringing fuel back to ISO 4406 specification does not mean that it will remain that way long-term. Fuel often falls out of specification through natural degradation, microbial growth, and the introduction of new contaminants via fuel transferring and new fuel loads. Be proactive and unnecessary prevent downtime.

Engineering Services

Products

Resource Center

Information

All company names, logos, and brands are property of their respective owners. Use of these names, logos, and brands does not imply endorsement.

Copyright © 2024 AXI International | All Rights Reserved.

Copyright © 2024 AXI International | All Rights Reserved.