Maximizing Efficiency: The Power of Fuel Metering and Net Fuel Consumption Monitoring

It's All About The Flow

The precise measurement of fuel flow and other fuel characteristics are vital across numerous industries.

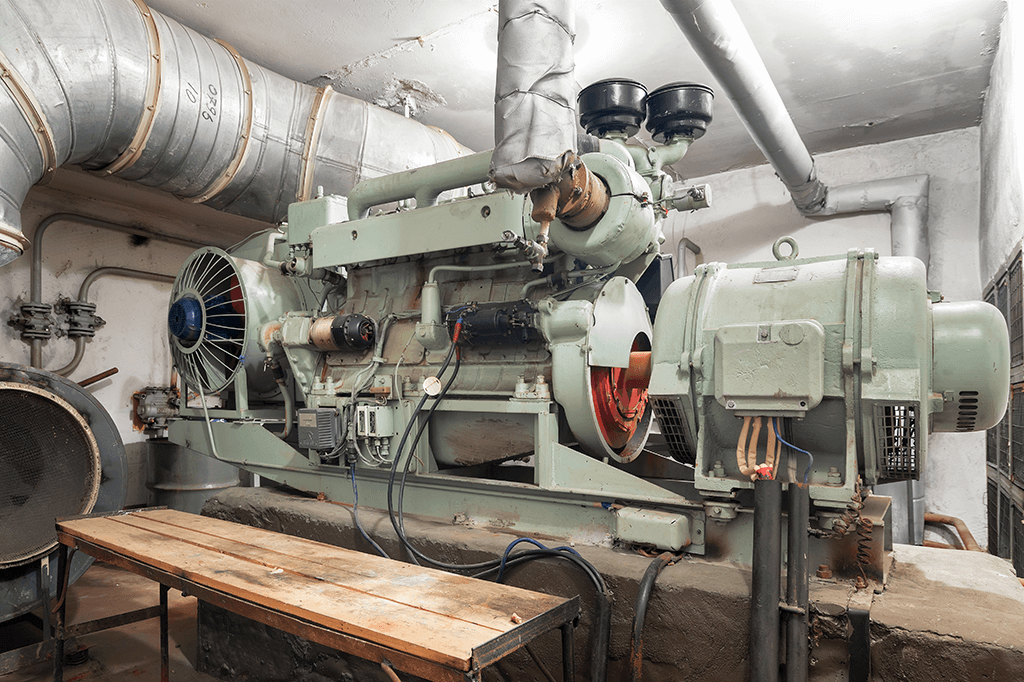

Whether it’s for propelling heavy equipment, generating electricity, or powering industrial processes, effective fuel management ensures safety, efficiency, and the smooth functioning of mechanical equipment such as engines, generators, or other heavy equipment.

In this article, we will explore the importance of fuel metering and monitoring in several key industries, including transportation, energy, and manufacturing, and discuss the benefits of measuring other various fuel characteristics as well.

Where are Fuel Metering Systems Used?

Fuel metering systems are commonly used in automobiles, airplanes, and ships to ensure that the engines receive the optimal amount of fuel for a given operating condition.

This is important not only for achieving maximum fuel efficiency and quantifying emissions but also for maximizing engine performance and reliability.

In the aviation industry, for example, fuel metering systems are used to precisely control the amount of fuel delivered to the engine at various stages of flight. This is critical for achieving optimal engine performance and ensuring safe operation of the aircraft.

In power plants that burn fossil fuels, fuel metering systems help to ensure that the correct amount of fuel is delivered to the combustion chamber to generate the desired amount of energy. This not only improves efficiency but also reduces emissions, as excess fuel can lead to incomplete combustion and the release of harmful pollutants.

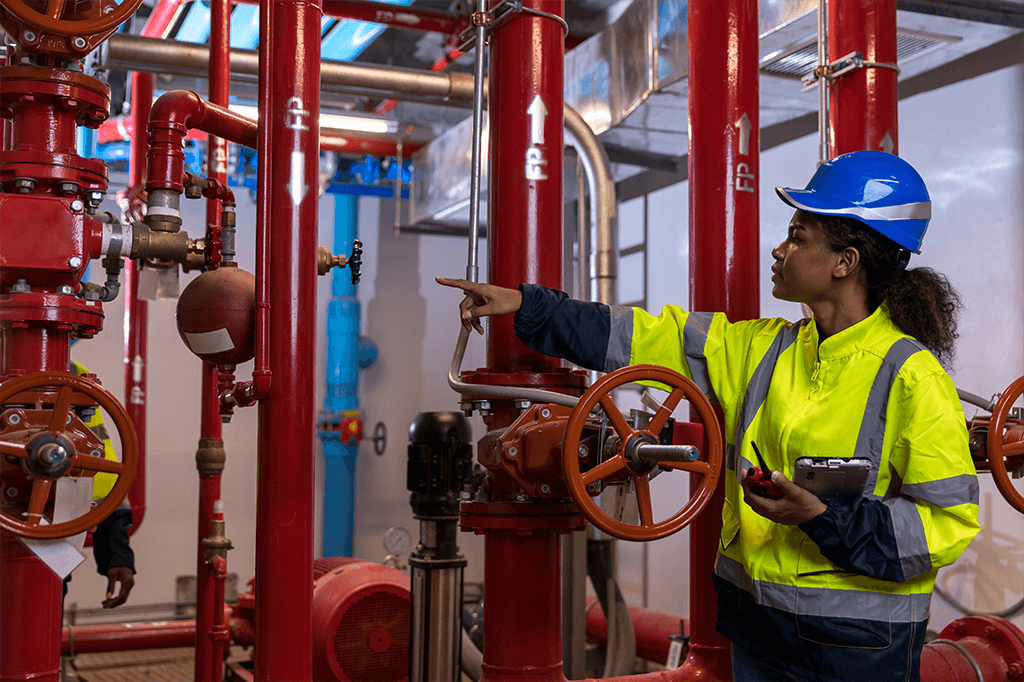

In the manufacturing industry, the same metering technologies are used to measure the flow-rate of different liquids in various industrial processes.

For example, in the chemical industry, metering systems are used to measure and control the flow of chemicals, ensuring that the facility operations are efficient and safe.

In the farming and food processing industries, metering systems are used to control the flow of liquids such as water or milk. This is done during various cooking and baking processes to ensure consistent quality and reduce facility waste.

Fuel metering is also important in industrial heating systems, such as those used in foundries or metallurgical processes. In these applications, fuel metering systems help to control the flow of fuel to the heating elements, ensuring that the temperature is maintained within a safe and efficient range.

Net Fuel Consumption Monitoring

Fuel consumption monitoring refers to the process of measuring and tracking the amount of fuel consumed by a vehicle, machine, or equipment over a specific period of time.

This monitoring is typically done using sensors, meters, or electronic devices that record the amount of fuel used during operation.

Fuel consumption monitoring is crucial for several reasons, especially in applications where these backup power systems play a crucial role, such as data centers, hospitals, and other essential facilities.

Fuel consumption monitoring systems serve several important purposes:

- Efficiency Tracking: It helps businesses and individuals track their fuel usage to identify patterns and trends, enabling them to optimize fuel efficiency and reduce costs.

- Performance Evaluation: Monitoring fuel consumption can provide insights into the performance of engines or systems. Consistent increases in fuel usage may indicate potential issues that need attention.

- Environmental Impact Assessment: By keeping track of fuel consumption, individuals and organizations can assess their environmental impact and identify opportunities to reduce carbon emissions.

- Preventative Maintenance: Monitoring fuel consumption can help anticipate maintenance needs by flagging any unusual changes in the fuel usage that may indicate underlying problems.

- Cost Management: Understanding fuel consumption patterns allows for better budgeting and cost management, especially in industries heavily reliant on fuel, such as transportation and logistics.

You Can't Improve What You Don't Measure

One of the greatest operational benefits of fuel metering systems is the ability to measure equipment performance and efficiency. The active monitoring of net fuel consumption allows facility managers to have real quantified insight into the health of mechanical operations. This is why it is ultimately important for flow meters to be accurate in their measurements.

This active monitoring/measuring is done automatically by the fuel monitoring system using meters that record the characteristics of fuel being sent to the engine(s) and then comparing that to the characteristics of the returned fuel.

By measuring the differential in values between these measuring points, the system is able to accurately calculate the net fuel consumption of the engine.

Fuel consumption monitoring systems are also used to help monitor engine performance. Thus when the consumption differential reaches irregular levels then it can signal the need for engine or equipment maintenance.

These fuel insights not only help equipment managers to better predict engine maintenance, but they also give them the critical data needed to optimize the cyclic operation of the equipment to prevent unnecessary downtime.

Overall, fuel consumption monitoring is a valuable tool for optimizing operations, promoting sustainability, and ensuring efficient resource management. By optimizing fuel consumption, reducing emissions, and improving process efficiency, fuel consumption monitoring can help to reduce costs, improve safety, and promote sustainable development.

The ability to measure and control the flow of fuel is essential in many industrial and economic processes. Within many industries, fuel metering and monitoring systems help to ensure efficient and safe operation of various equipment and systems.

As such, continued investment in fuel metering technology and research is critical for the success of many industries and the overall health of our economy and environment.